Three types of spinning systems are available in a wide range of short staple spinning. Carded and combed yarns in ring spinning are produced according to yarn quality, cost as well as time cost requirements. Carded yarns are highly used for medium quality and average count, which are used for all types of fabrics.

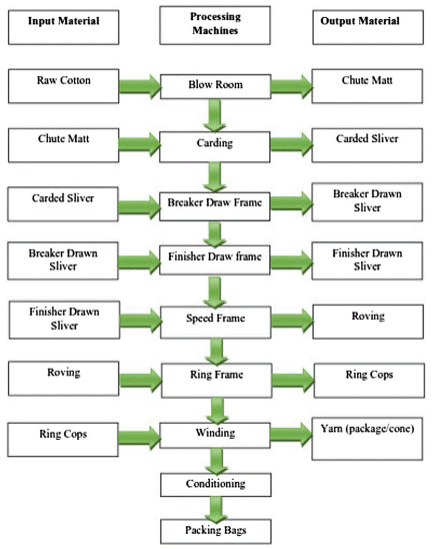

Flow Chart for Carded Yarn Manufacturing Process:

Fiber → Blow Room → Lap

↓

Lap → Carding → Card Sliver

↓

Card Sliver → 1st Drawing Frame → Drawn Sliver

↓

Drawn sliver → 2nd drawing frame → Drawn sliver

↓

Drawn sliver → simplex → roving

↓

Roving → ring frame → yarn

↓

winding

↓

Reeling

↓

bundling

↓

Bailing

Combed yarn is a much higher quality yarn than carded yarn because there are shorter fibers and naps as well as impurities removed by the combing action. High quality yarn can be produced using combing machine in machine sequence. In cotton count, the finer the yarn. The number of combed yarns is high with best quality in fabric making.

Combed Cotton Yarn Manufacturing Process:

Fiber → Blow Room → Lap

↓

Lap → Carding → Card Sliver

↓

Card Sliver → Pre-Comb Drawing Frame → Sliver (Pre-Drawing)

↓

Sliver → Lap Former → Lap

↓

Lap → comber → comb sliver

↓

Comb Sliver → Post-Comb Drawing Frame → Painted Sliver (Post-Drawing)

↓

Drawn sliver → simplex → roving

↓

Roving → ring frame → yarn

↓

winding

↓

Reeling

↓

bundling

↓

Bailing

Combed yarns are often used to make luxury garments to produce high quality fabric. Comfort as well as handling appeal is high in garments made from worsted yarn.