Cotton fiber contains a lot of dust, foreign matter, seeds and other particles. During the spinning of cotton yarn, waste is generated at various stages. Some of them are recyclable, others are not. Now let’s give them name and production area or machine name.

DROPPING 1

It is made on carding machine. It is not used in export factories. However, it can be used in rotor spinning.

DROPPING 2

It is manufactured in clean rooms. It is not used in export factories. However, it can be used in rotor spinning.

Hard dust

It is made in ring frame and wrapped area. It is unusable waste.

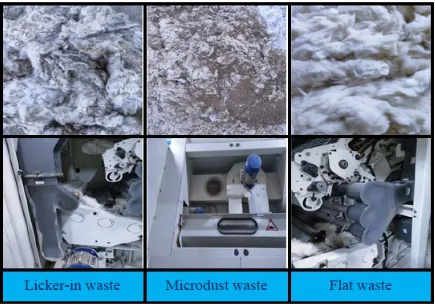

Micro dust

We collect this dust from air conditioners. It is unusable waste.

Filter waste

It is produced in different areas of the spinning mill and collected from the air conditioning system.

Dirty cotton

It is caused due to mishandling of workers.

Fine dust

It is collected from the air conditioning system. It is unusable waste.

Sweep

Produced in different areas of spinning mill and collected by air conditioning system

PNEUMAFILE

Made in ring frame. When the last crack forms, increase the amount of Pneumafil. It is recyclable waste. Mainly used in rotor spinning mills. It is not used in outpace spinning mills. attachment It is non-recyclable waste.

Roving

Made in simplex and ring frames. This waste can be recycled. Throw away, reuse. It also increases due to mismanagement by workers

Banda

Made in ring frame. When cotton bales contain more small fibers, bonda waste increases. It depends on the high end break as well as temperature and RH%. Bonda is recyclable waste. But not used in export spinning mills. Mainly used for machine faults in rotor spinning mills.